How SpectroPyrometer Technology Works

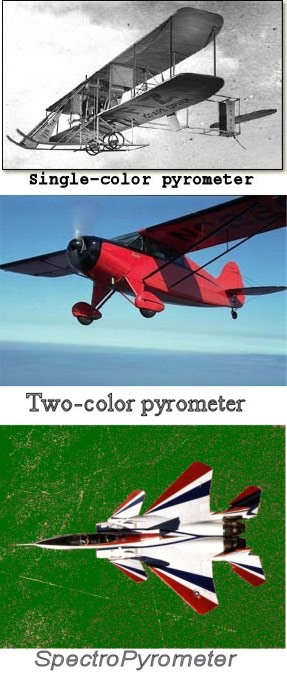

There are three types of pyrometer (or radiation thermometer). In chronological order of development they are

There are three types of pyrometer (or radiation thermometer). In chronological order of development they are

- the brightness pyrometer (single color),

- the ratio pyrometer (two color), and

- the multi-wavelength pyrometer (three or more colors).

The FAR SpectroPyrometer is a multi-wavelength pyrometer using hundreds of colors.

FAR SpectroPyrometer

The FAR SpectroPyrometer is an expert system multi-wavelength pyrometer that collects hundreds of discrete thermal radiation intensities, each at a different wavelength. Out of these hundreds of discrete wavelength/intensity values it can mathematically construct hundreds of thousands of pyrometers. If these virtual instruments all agree, the analysis is simple: the agreed-upon temperature is the answer. If they all disagree the expert system knows this means the emissivity is changing. It then examines how they disagree to determine how the emissivity was changing (at the exact moment of the measurement, not before or after). If the disagreement is localized in some part of the thermal spectrum, the expert system can detect the offending spectral area and eliminate it from the calculation. After the analysis, the instrument reports the average temperature and standard deviation over the entire range it has decided to use. The standard deviation is identified as the tolerance, and is a direct, immediate measurement of the accuracy of the exact temperature determination just made. Finally, the instrument reports the signal strength at a central wavelength. The signal strength is equivalent to the emissivity if a number of conditions are met: the field of view is filled, the optics are clean, and there is no attenuation from the environment between the target and the instrument.

Advantages of the SpectroPyrometer

- The tolerance, an entirely new feature, tells the user what degree of confidence to have in the just-made measurement. It is hard to overstate the value of this knowledge: when difficulties occur, it is immediately evident whether or not temperature control is the root of the problem.

- Accuracy: the extremely large amount of data translates directly to extreme accuracy: the instrument routinely achieves ±0.1% accuracy on known targets.

- No operator burden of information to be entered: Changes in emissivity due to processing, target variation, or environmental interference from one measurement to the next are accommodated; the target composition doesn’t even matter. This is a huge advantage in factories where several different materials are processed (e.g., investment casting foundries).

- The signal strength indicates how the emissivity is changing with processing; this can be used as a process or product quality diagnostic.

- Noise effects, particularly problematic in ratio and other multi-wavelength pyrometers, are reduced to unimportant levels.

Brightness (single color) pyrometer

These add up all the thermal radiation intensity in some range of wavelengths (the sensitive area of the instrument’s detector, or bandwidth of the detector) and relate it to temperature through linearizing electronics or a look-up table. The instrument’s sensitivity may vary across the bandwidth, making it difficult to use published values of emissivity, especially those of metals, which change with wavelength. For these instruments, the emissivity value is either entered by the operator or assumed to be unity. Many manufacturers supply emissivity information with their instruments. These abbreviated lists are hopelessly simplified. The reality is that emissivity is affected by many things, and even the most commonly-used refractory materials vary wildly. The most common brightness pyrometer is the vanishing filament pyrometer, which came to prominence in the early 1900s. Biggest problems: emissivity is often unknown or changing; anything that affects the radiated intensity (sight glass, dirt, smoke, steam, process or combustion gases) affects the temperature.

Ratio (two color) pyrometer

These instruments, which date from about the middle of the last century, use two detectors to add up all the intensity in two wavebands and then relate the quotient of the two intensities to temperature, again by look-up table or linearizing electronics. In ideal cases (black or greybodies) the emissivity cancels out. In non-ideal cases, the operator is expected to enter the relative emissivity. Biggest problems: emissivity often changes with wavelength (some sight glasses mimic this problem as their transmission changes with wavelength); ratio instruments lack the precision of brightness pyrometers and are susceptible to noise (differences in intensity at the two wavelengths are relatively small). Relative emissivity is even less well-known than the absolute value of emissivity; errors can be extremely large if one color is affected more than the other by an environmental or material variation.

Wavelength in pyrometry

Manufacturers of traditional pyrometers typically quote an operating wavelength (or wavelengths in the case of a two-color instrument) when they actually mean a finite range of wavelengths, or a bandwidth. A typical one or two-color pyrometer bandwidth ranges from 50 to 500 nanometers. The bandwidth for the SpectroPyrometer is 2 nanometers or less. This very narrow bandwidth for each wavelength of the SpectroPyrometer is an advantage: when the emissivity is changing with wavelength it is not averaged over a wide spectral area, so it’s possible for the expert system to unravel the emissivity’s behavior.